Chemcote Speciality Coatings provide Value Added Services that validate Coating Performance in varying site and extreme environmental conditions. Coating Performance Testing is conducted under controlled conditions that are at best simulation of a typical site or environmental condition. The parameters tested normally are used as bench marks for coating performance and form the basis of any coating evaluation and selection process. No two sites have identical environmental conditions and site validation of speciality coating products' performance under prevailing environmental site conditions require Specialist Applicators and Specialist Equipment. In short the coating product's long term performance hinges on quality coating installation. We have a team of multi disciplined Specialist Applicators, with Customized Specialist Equipment, who have the skill sets and experience to mitigate all site and environmental anomalies.

Chemcote Speciality Coatings provide Value Added Services that validate Coating Performance in varying site and extreme environmental conditions. This in many cases involves taking on Projects on a turn key basis with our partners. One such area is in Underwater Coating Application. Having had over 6 years’ experience in the field, we have encountered and installed successfully underwater coating systems in both Freshwater and Sea Water. We have mitigated for site conditions like the presence cathodic protection (both active and passive), soft marine growth and existing corrosion protection systems such as wraps and clamps.

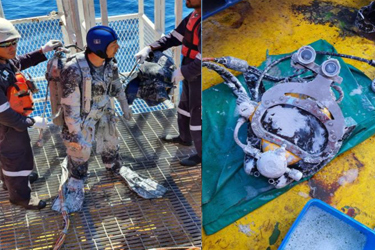

Demonstrational videos of underwater coating application carried out in static conditions like in a glass tank with clean tap water are very misleading and can have very different results when done in real site conditions as can be seen in the pictures on the left. Everything else gets coated except the intended submerged substrate. These type of videos are gimmicks at best and should NEVER be an endorsement for coating product selection in actual on site underwater application.

Underwater Coating Application is both an Art and a Science. The “Science” is in Engineering the Chemistry of a coating product to mitigate ALL environmental conditions in submerged surfaces be it in Sea Water or Freshwater. Chemcote Speciality Coatings (SEA), a specialist coatings manufacturer from Singapore have developed coating products that totally displace water, wetting out and encapsulating submerged substrates, allowing submerged surfaces to be coated with relative ease using simple tools and equipment. The “Art” is in providing good Technical Support for products during site installation that validates ALL coating performance parameters in real site environments. Chemcote Speciality Coatings (SEA) P/L has appointed exclusively & licensed "Oakdene Services Pte Ltd" to provide global technical support services for a range of underwater coating services.

A vital partner who is critical for the success of all our Underwater Coating Installation projects is specialist diving contractor, our exclusive Underwater Specialist Applicator. Their team of professional divers with custom designed equipment makes our coating products look good and unleashes the full coating performance potential in extreme environments. Training is absolutely vital in Underwater Coating Application Projects .All the current standards for surface cleanliness and painting procedures are written for above water (atmospheric) coating applications, which means environmental conditions are modified to accommodate process and methodology. Lack of awareness on the progression in coating technologies, surface preparation methods and to a certain extent coating application methods have led to outdated practices still being promoted and endorsed. Training allows us to create awareness and increase competence at all levels, from Applicators to NACE 3 Coating Professionals.

Underwater Surface Preparation technology and methods have progressed to such an extent that the surface standards achieved above water can be achieved underwater as well without the need of coffer dams that modify the environment. Combined with advances in coating technologies, we can customize surface preparation and coating application for Under Water Projects delivering on performance equalling any Projects above water to exacting standards such as NORSOK 501.

Fabric and Infrastructure of Aging Production Assets Offshore require maintenance to extend its operating life. Chemcote Speciality Coatings work with our partners to provide Solutions in the area of Total Corrosion Management to Prevent corrosion, Protect both submerged and exposed substrates in order to Preserve Production Assets thereby extending 'in service' life cycles

We provide integrated inspection services using multi disciplined IRATA certified rope access technicians who can carry out inspections, asses existing coating performance, carry out coating failure analysis and make recommendations for repair and refurbishment of existing coating system with Chemcote's range of high performance coating products.

Our range of specialist coating products used in combination with composite reinforced mesh comprising either Basalt, Kevlar, Carbon Fibre and GRP offer a seamless "cold repair" solution for deck plates, pipelines and pipe supports (CUPS). The repair solutions are not only safe, offering corrosion protection but also restore structural integrity with quick turnaround of production assets.

Our specialist range of coating products and composite repair systems are installed in extreme environments which defy the current standards of surface cleanliness set by both NACE and ISO. These standards are written around ambient conditions and do not cover coating application on wet surfaces or coating application underwater in permanently submerged surfaces. This Paradigm shift requires proper training to ensure competence. We provide a comprehensive Training Program for Applicators, Supervisors and QA personnel.